Solutions for Light Crude and Condensates

Our MERICAT™ technology is ideal for the treatment of whole crude, including crude sweetening. THIOLEX™ is effective in sulfur extraction, with REGEN® ensuring minimal caustic is needed as the caustic stream is continuously regenerated. The contaminants removed include:

- Hydrogen Sulfide (H2S)

- Mercaptans (RSH)

- Carbonyl Sulfide (COS)

- Carbon Dioxide (CO2)

- Organic or Naphthenic Acids (RCOOH)

Maximizing Efficiencies for NGL or LPG

To aid in the removal of RSH in NGL or LPG, Merichem Technologies can provide a cost-efficient caustic treating unit with a small footprint. With this implementation, caustic is spent to the maximum possible extent. For units consuming larger quantities of virgin caustic, spent caustic can be regenerated with our REGEN® technology.

Our technologies are supported with integrated engineering and modular fabrication capabilities, as well as catalyst supply and technical services. Merichem Technologies can offer complete treatment units or proprietary equipment, working from your specifications or our own standardized requirements. We provide full-scope project services that include project management, project controls, engineering and design capabilities, as well as service after the sale with our technical services group. Our goal is to ensure your success with each project.

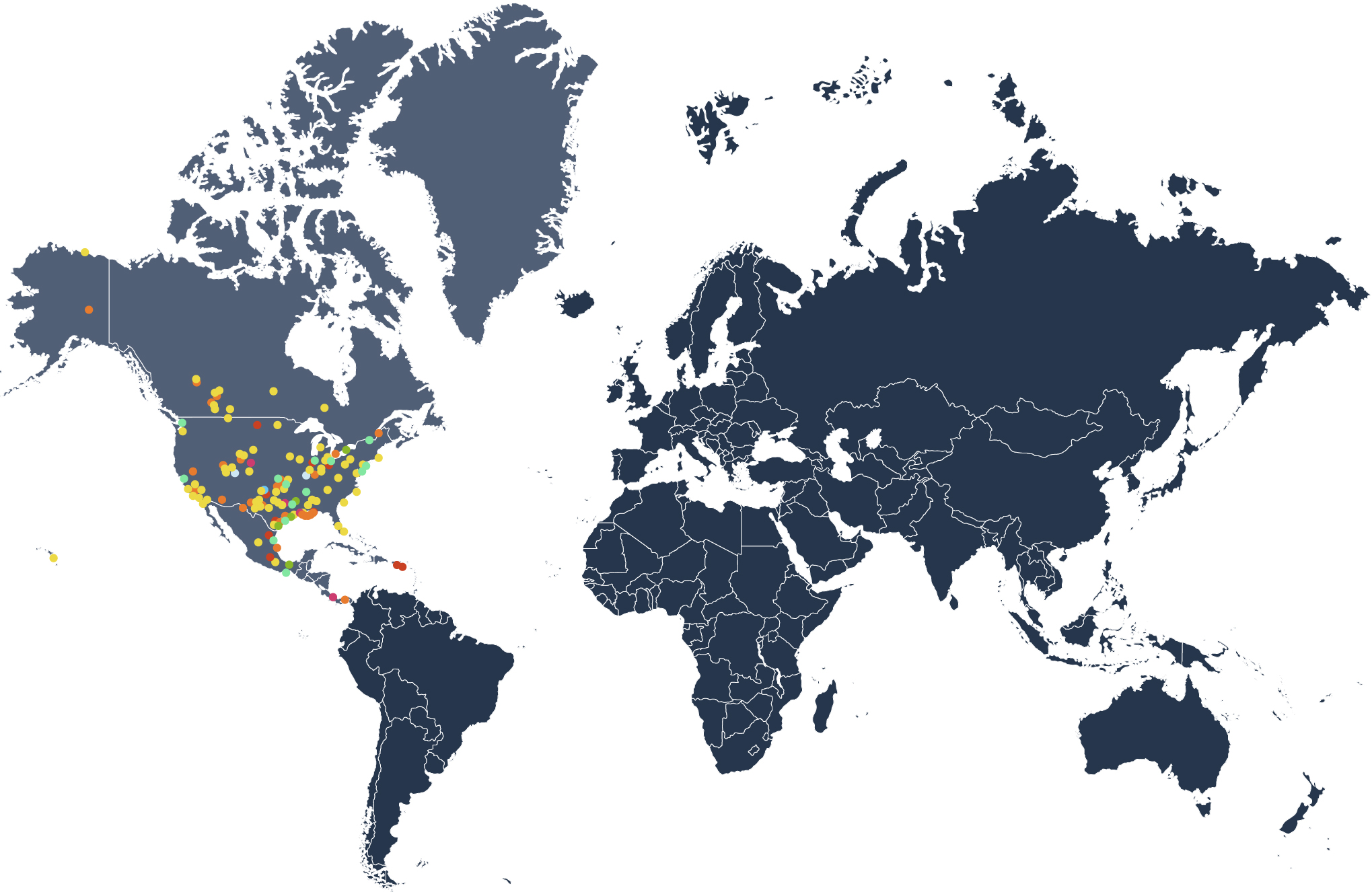

North America

- 5 AMINEX™ Units

- 21 AQUAFINING™ Units

- 126 LO-CAT® Units

- 70 MERICAT™ Units

- 13 MERICAT™ II / J Units

- 2 MERICON™ Units

- 19 NAPFINING™ Units

- 26 REGEN® Units

- 153 THIOLEX™ Units

South America

- 3 AMINEX™ Units

- 14 AQUAFINING™ Units

- 8 LO-CAT® Units

- 4 MERICAT™ Units

- 6 MERICAT™ II / J Units

- 8 MERICON™ Units

- 12 NAPFINING™ Units

- 8 REGEN® Units

- 26 THIOLEX™ Units

Africa

- 1 AQUAFINING™ Units

- 3 LO-CAT® Units

- 1 MERICAT™ Units

- 1 MERICAT™ II / J Units

- 4 NAPFINING™ Units

- 1 REGEN® Units

- 2 THIOLEX™ Units

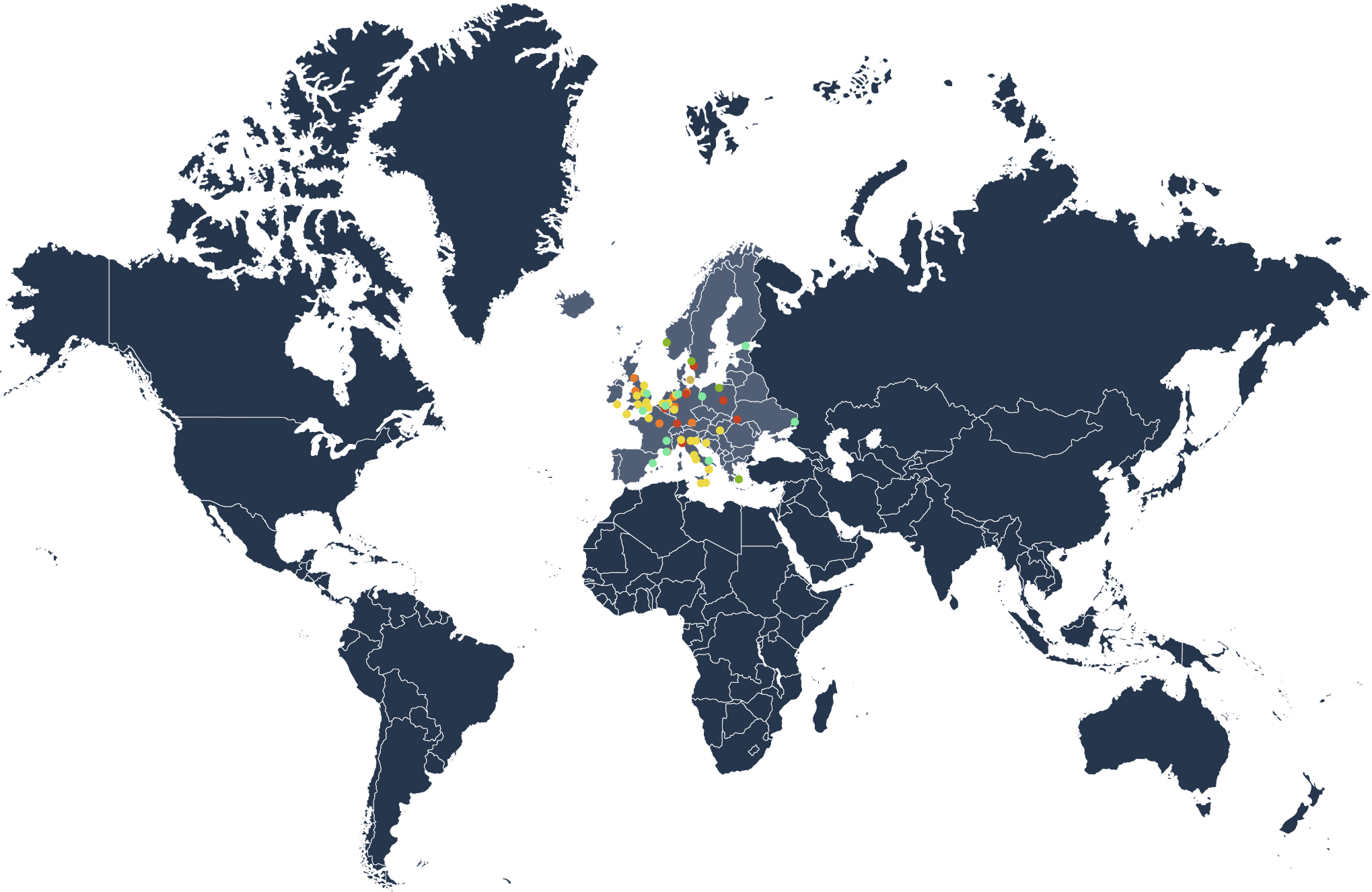

Europe

- 6 AMINEX™ Units

- 23 AQUAFINING™ Units

- 29 LO-CAT® Units

- 21 MERICAT™ Units

- 10 MERICAT™ II / J Units

- 5 MERICON™ Units

- 14 NAPFINING™ Units

- 6 REGEN® Units

- 43 THIOLEX™ Units

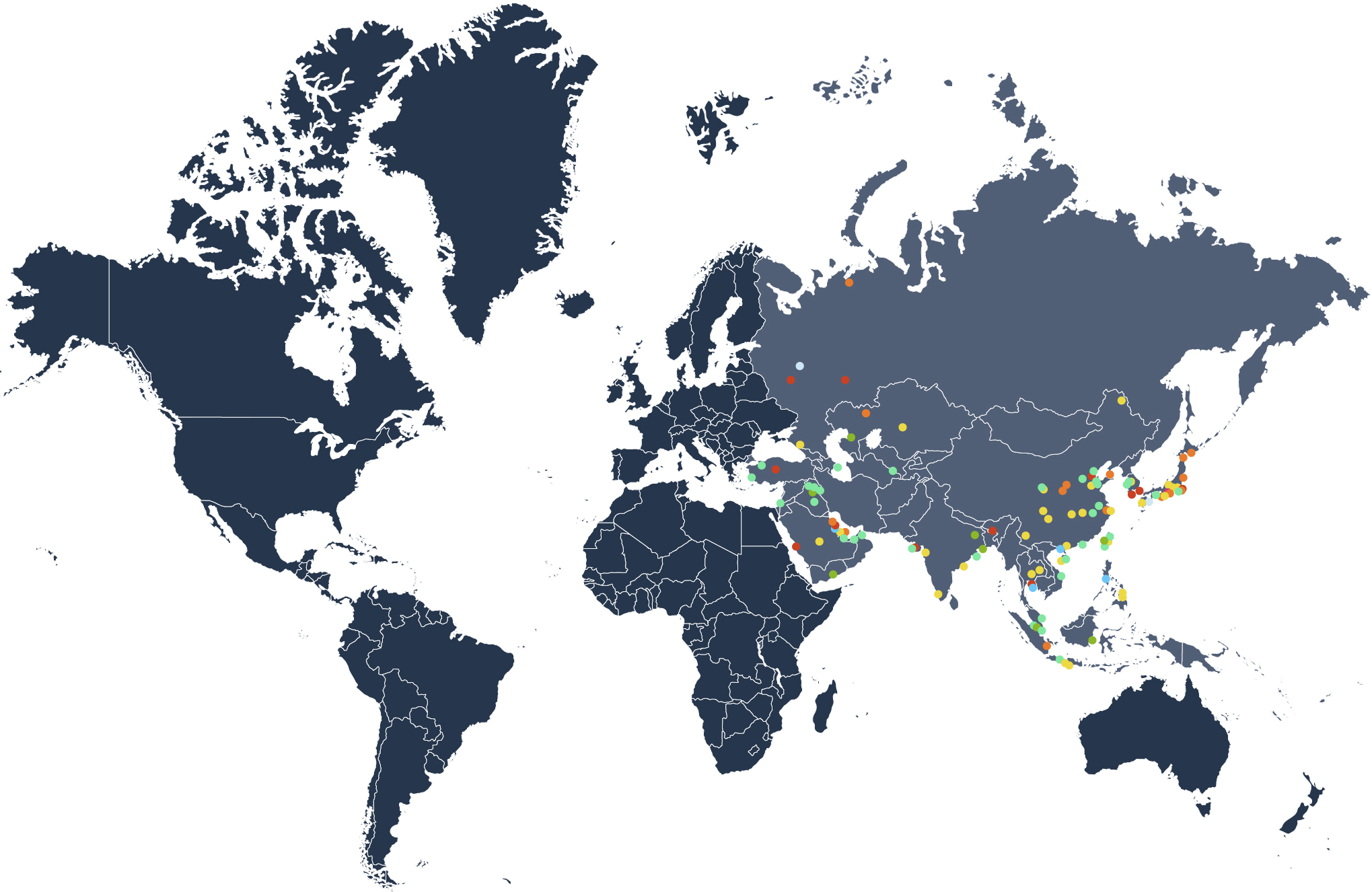

Asia

- 18 AMINEX™ Units

- 44 AQUAFINING™ Units

- 52 LO-CAT® Units

- 59 MERICAT™ Units

- 22 MERICAT™ II / J Units

- 20 MERICON™ Units

- 32 NAPFINING™ Units

- 20 REGEN® Units

- 121 THIOLEX™ Units

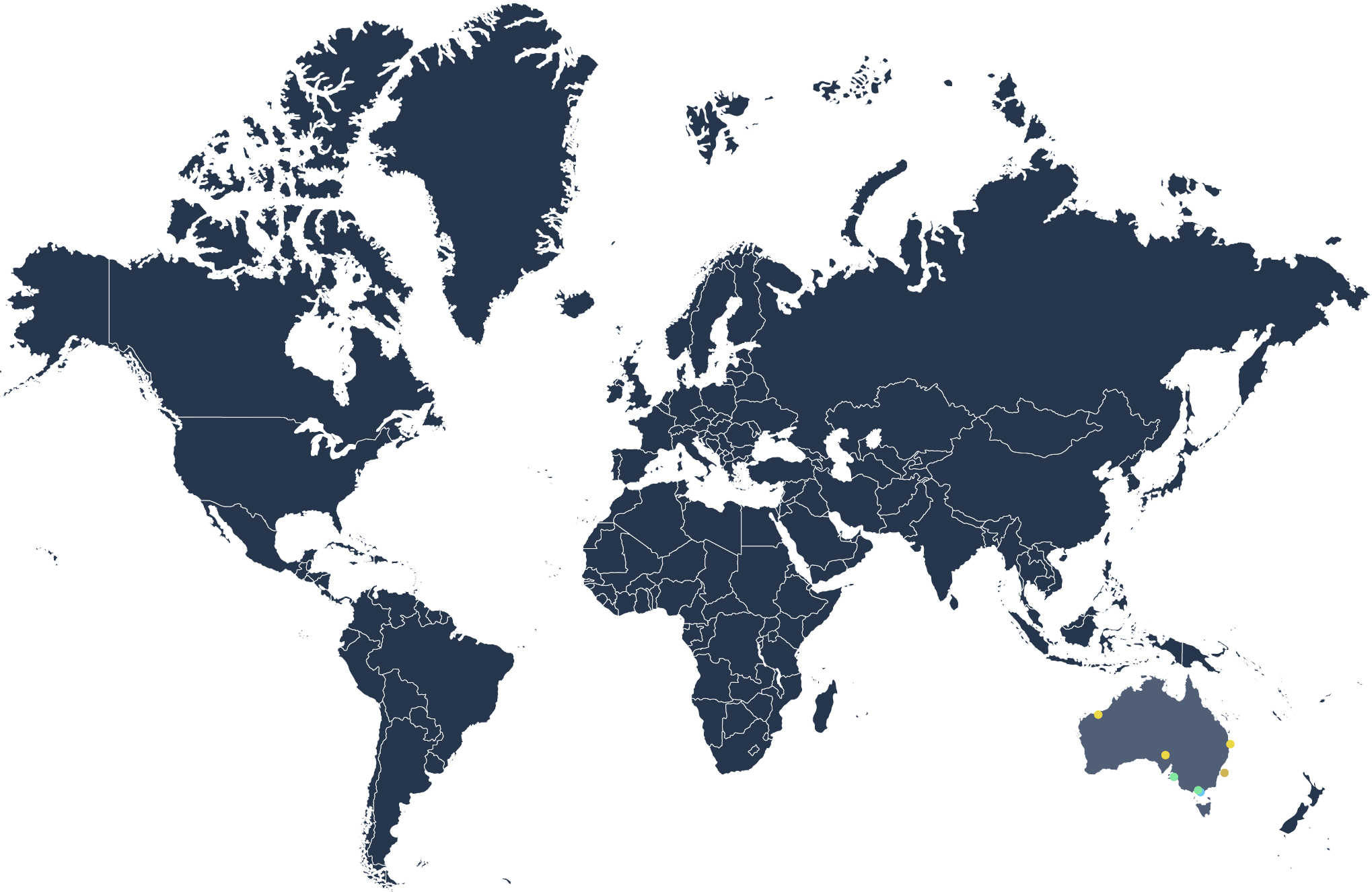

Australia

- 2 AQUAFINING™ Units

- 9 LO-CAT® Units

- 2 MERICON™ Units

- 2 NAPFINING™ Units

- 1 THIOLEX™ Units

AMINEX™

AQUAFINIG™

ESTEREX™

LO-CAT®

MERICAT™

MERICAT™ II / MERICAT™ J

MERICON™

NAPFINING™

REGEN® / REGEN® ULS

THIOLEX™

Proven Worldwide

With over 1,250 licenses, Merichem Technologies has assisted upstream customers all over the world with hydrocarbon treatment systems.